Features

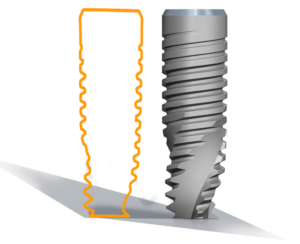

Semi conical shape with V-shaped threads: The implant body and thread shape is designed for mild bone compression while achieving maximum initial and long term stability.

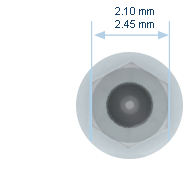

Internal hexagon connection: M4 implants feature an internal hex. connection. This well established connection assures proper abutment seating, anti-rotational engagement, resistance to lateral forces, excellent esthetic results and more.

A flat cutting apex allows for final adjustments during placement procedures.

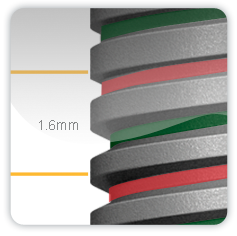

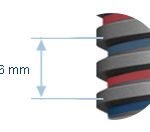

Dual thread design enhances placement procedure while being gentle to the surrounding bone. The overall insertion rate of M4 is 1.6mm per revolution.

Wide range of prosthetic options and components

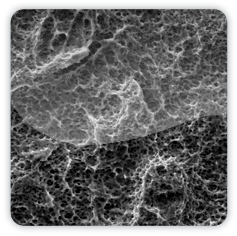

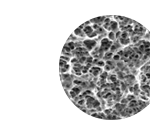

Surface treatment: The surface roughness and micro-morphology is a achieved by a combination of sand blasting and acid etching. MIS� established surface technology has provided millions of patients and clinicians with excellent osseointegration results and long lasting clinical success.

Raw material: All MIS implants are made from Ti-6Al-4V ELI (Grade 23), the higher purity version of Ti-6Al-4V. This specific type of alloy combines biocompatibility, excellent fatigue strength and low elastic modulus. These benefits make Ti-6Al-4V ELI mechanically superior to titanium grade 4 and the ultimate dental and medical titanium grade. Similarly to commercially pure titanium (Grades 1-4), the outer surface of all MIS implants are comprised of a thin layer of pure titanium oxide (TiO2).

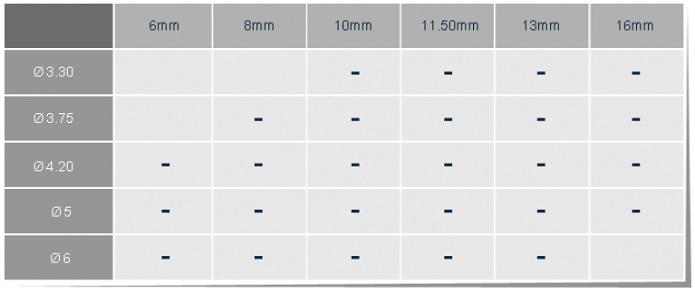

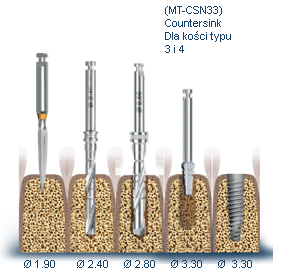

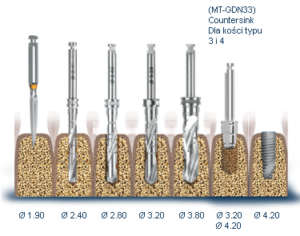

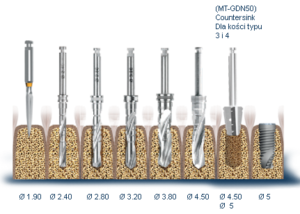

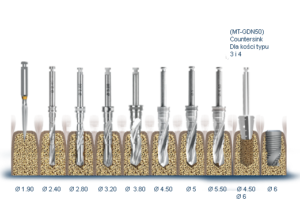

Implant's sizes